WHI GLOBAL

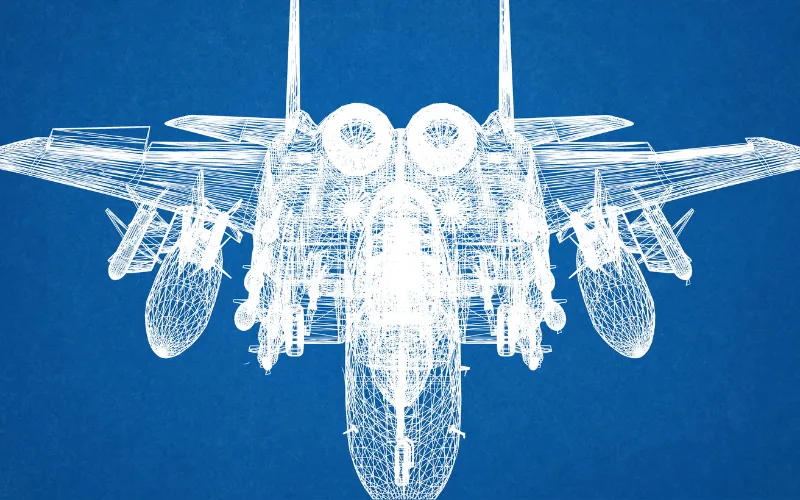

Aerospace

Defense

& Industrial Markets

WHI is a vertically integrated manufacturer of precision components and complex assemblies for the aerospace, defense and industrial markets.

WHI Global Markets

WHI has a wide array of equipment and capabilities which allow us to serve a variety of end markets.

Aerospace Market

Our extensive experience in meeting the exacting needs of the aerospace industry allows us to provide precise and integrated solutions that improve performance, reduce costs and shorten lead times. With extensive capabilities in forging, precision machining, assembly, engineering, inspection and NADCAP processes, WHI is an ideal partner to serve as a one-stop-shop for aerospace customers.

Defense Market

WHI works with both governmental and private entities to meet the needs of the defense industry by providing the highest quality products while meeting strict delivery requirements. As a result of our expertise and focus on quality, WHI forgings and machined components can be found in a variety of military and defense applications including aviation, weaponry and ordnance.

Industrial Market

WHI has been a trusted partner to industrial customers for decades. With a broad range of state-of-the-art equipment and a highly experienced workforce, WHI is capable of manufacturing complex components from nearly any material while also ensuring the highest quality and on-time delivery.

Semiconductor Market

The complex world of semiconductor and device manufacturing requires familiarity with a nearly infinite number of process and equipment variables. WHI’s long history supplying precision machined components for applications in the semiconductor industry has allowed our team to become experts in the finishing, cleaning, testing, and handling of items for semiconductor equipment manufacturers.

WHI Capabilities

WHI’s extensive array of equipment and 65 years of manufacturing experience enables us to provide our customers with high quality parts and assemblies. WHI offers a multitude of services and solutions including:

commitment to excellence

Our World Class Facilities

Three ITAR registered facilities carrying AS9100D & ISO 9001 certifications.

WHI has over 250,000 square feet of world class manufacturing space, with all facilities possessing the latest ISO 9001 and AS 9100D certifications.

Fort Worth, TX

98,000 square foot manufacturing facility

6 hammers and 12 hydraulic and mechanical presses, screw press

Inventory of over 5,000 proprietary forging dies

In-house die tool development and manufacture

NADCAP certified Heat Treat and Non-Destructive Testing

ISO 9001 and AS 9100D certifications

Tulsa, OK

60,000 square foot manufacturing facility

29 total CNC machines including 22 CNC mills and 6 CNC turning centers

Waterjet cutting, hydroforming and specialty finishing capabilities

5,000 square feet of dedicated assembly space

ISO 9001 and AS 9100D certifications

Springfield, MA

60,000 square foot manufacturing facility

3 autoclaves up to 17 x 8 ft, 9 ovens, 6 presses and 3 clean rooms

Layup, bonding, rubber vulcanization and compression molding capabilities

FAA certified repair station

ISO 9001 and AS 9100D certifications

WHI Global Recent Equipment Additions

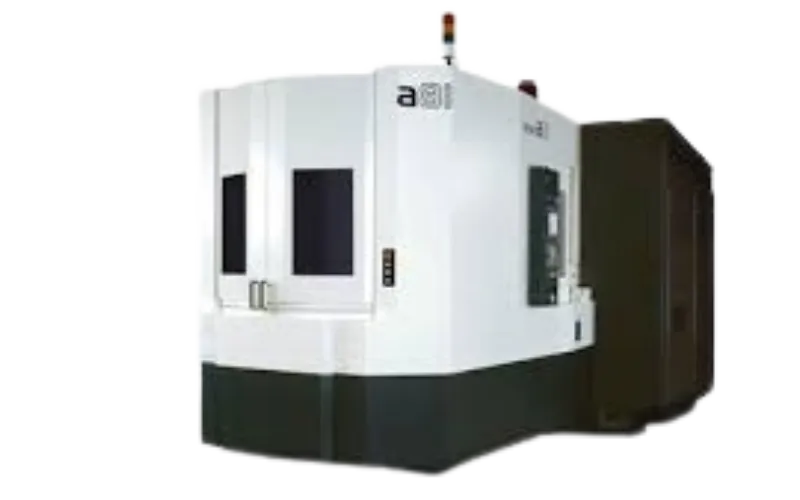

MAKINO MAG3 5-AXIS HORIZONTAL MACHINING CENTER WITH 10-PALLET SYSTEM

MAKINO A81/A88 HORIZONTAL MACHINING CELL WITH 20 PALLET SYSTEM

DOOSAN PUMA V400 VERTICAL TURNING CENTER

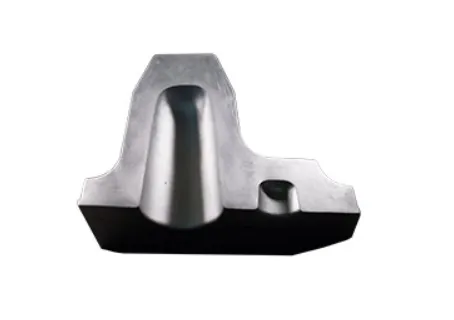

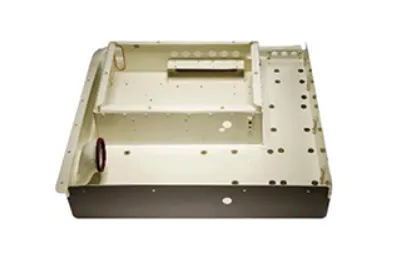

WHI Global Featured Products and Capabilities

WHI Global designs, develops and produces custom forgings for mission critical applications..

WHI Global has experience fabricating highly complex compositec components..

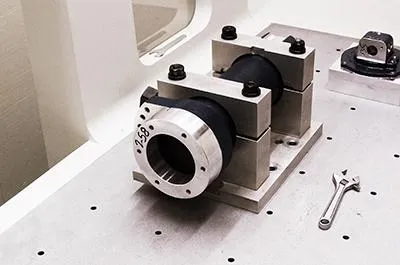

WHI Global has extensive Machining and finishing cababilities to produce complex low tollerance parts.

A Passion for Quality

A Commitment to Excellence

Quality is fundamental to high-precision CNC machining and critical to our customers, so we make substantial, ongoing investments to ensure our Quality System meets and exceeds the most demanding requirements.

Our ability to consistently produce complex components is based on a highly engineered process that doesn’t degenerate as it scales — for stable, predictable, repeatable parts manufacturing that eliminates variables in product commercialization and manufacturing.

Our quality engineers oversee quality management systems specifically designed for ultra-tight tolerances and high-precision machining technology. They work closely with our manufacturing engineers, plant managers and plant associates to monitor and maintain processes that ensure that even the most challenging components we produce today meet and exceed all customer requirement time after time.

As a testament to our emphasis on producing high quality forged and machined parts, WHI’s facilities have maintained ISO 9001 and AS9100 certifications since 2000, and our Fort Worth facility has maintained NADCAP accreditations since 2004.

Schedule a Meeting with us

Let us bid on your next big project. Book a meeting with us and let's connect to talk about how we can help.

WHI Partners

Follow US

WHI is a vertically integrated manufacturer of precision components and complex assemblies for diversified end markets. With industry-leading closed-die forging, composite fabrication, 3-, 4- and 5-axis CNC machining, assembly and NADCAP capabilities, WHI has served a global customer base since 1951.

©2023 WHI Global, LLC. All rights reserved.

Designed and Powered by OttoMate 360