WHI GLOBAL

WHI’s heritage dates back over 70 years, and involves many individual and

collective contributions that make up the company we know today.

About WHI Global

WHI is a vertically integrated manufacturer of complex metal parts and assemblies for the aerospace, defense and industrial markets. WHI’s operating history dates back to 1951 with a 260,000 sq. ft. manufacturing footprint that includes four ITAR registered facilities carrying AS9100D & ISO 9001 certifications.

WHI utilizes a broad range of state-of-the-art equipment and support systems to deliver superior value to our customers. With industry-leading closed-die forging, composite fabrication, 3-, 4- and 5-axis CNC machining, assembly, NADCAP heat treating, testing and inspection capabilities, WHI is well positioned to produce high quality components from virtually any metal or composite material in a variety of sizes and complexities. With integrated systems, engineering expertise and an experienced workforce,

WHI is able to meet and exceed even the most stringent delivery requirements. WHI has long-standing relationships with many of the largest and most respected companies in its markets, and our diverse, long-standing supply chain drives shorter lead times and reduced costs for complex, mission critical components.

WHI is committed to the continuous improvement of its processes and procedures, with product quality and customer satisfaction being top priorities. WHI has a dedicated workforce of ~250 machinists, forgemasters, layup technicians, engineers, assembly, inspection and support personnel, many of whom are industry veterans with decades of experience.

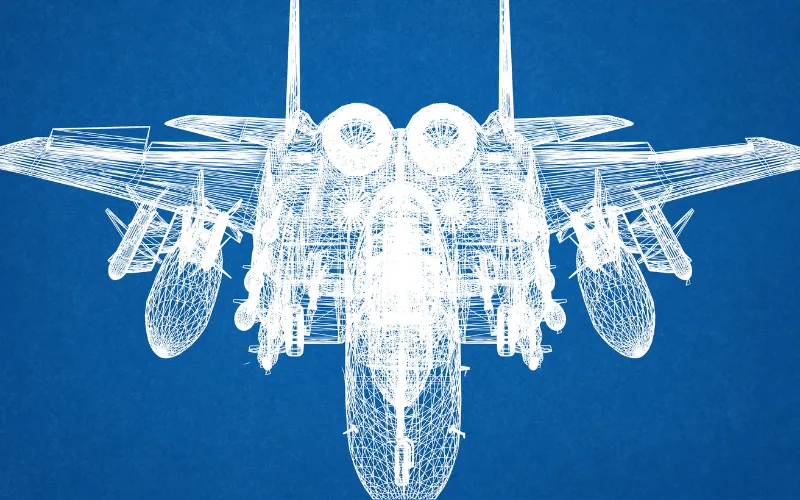

WHI manufactures components for a wide variety of commercial and military platforms including: 787, 777, 767, 747, 737, G650, G550, G280, HondaJet, C-17, F-15, F-16, C-17, C-130, KC-135, AH-64, CH-47, UH-1, UH-60, S-76, E-2D, B-52, B-2, and V-22 among others. WHI maintains an inventory of over 5,000 forging dies as well as an extensive array of composite tooling and machining fixtures to expedite the production of replacement and/or spare parts.

Prototyping

Tool Design & Manufacturing

Engineering Services

Closed-die Forging

Composite Fabrication

3-, 4- & 5-axis CNC Machining

NADCAP Certified Processes

Kitting & Assembly

WHI FACILITIES

WHI has over 250,000 square feet of world class manufacturing space, with all facilities possessing the latest ISO 9001 and AS 9100D certifications.

FORT WORTH, TX

98,000 square foot manufacturing facility

6 hammers and 12 hydraulic and mechanical presses, screw press

Inventory of over 5,000 proprietary forging dies

In-house die tool development and manufacture

NADCAP certified Heat Treat and Non-Destructive Testing

ISO 9001 and AS 9100D certifications

TULSA, OK

60,000 square foot manufacturing facility

29 total CNC machines including 22 CNC mills and 6 CNC turning centers

Waterjet cutting, hydroforming and specialty finishing capabilities

5,000 square feet of dedicated assembly space

ISO 9001 and AS 9100D certifications

SPRINGFIELD, MA

60,000 square foot manufacturing facility

3 autoclaves up to 17 x 8 ft, 9 ovens, 6 presses and 3 clean rooms

Layup, bonding, rubber vulcanization and compression molding capabilities

FAA certified repair station

ISO 9001 and AS 9100D certifications

Forth Worth, TX

Tulsa, OK

Springfield, MA

Quality Engineering

Quality is fundamental to high-precision CNC machining and critical to our customers, so we make substantial, ongoing investments to ensure our Quality System meets and exceeds the most demanding requirements. Our ability to consistently produce complex components is based on a highly engineered process that doesn’t degenerate as it scales — for stable, predictable, repeatable parts manufacturing that eliminates variables in product commercialization and manufacturing.

Our quality engineers oversee quality management systems specifically designed for ultra-tight tolerances and high-precision machining technology. They work closely with our manufacturing engineers, plant managers and plant associates to monitor and maintain processes that ensure that even the most challenging components we produce today meet and exceed all customer requirement time after time. As a testament to our emphasis on producing high quality forged and machined parts,

WHI’s facilities have maintained ISO 9001 and AS9100 certifications since 2000, and our Fort Worth facility has maintained NADCAP accreditations since 2004.

Commitment to Excellence

WE FOSTER EDUCATION

Our objective is to fully engage and motivate each team member to reach their full potential and contribute to our corporate success. WHI provides extensive training programs and utilizes a mentorship model to help junior employees expand their skill set and adopt best practices from our most tenured managers.

WE MAINTAIN THE HIGHEST STANDARDS

All WHI employees share responsibility to maintain the highest legal and ethical standards. Performing with integrity is a way of life and vital to the Company’s success. The WHI Code of Conduct is actively enforced at all facilities. This includes maintaining a safe and secure workplace for all employees and visitors.

WE ENCOURAGE INNOVATION

WHI supports the continuous improvement of its processes and procedures, with product quality and customer satisfaction being our top priorities. Together we strive to innovate, individually and as a team, to provide our customers with an unsurpassed level of service.

WE FOCUS ON DETAILS

Responding to our customer’s needs quickly, efficiently, and effectively reflects our small company attitude with our large company capabilities. With every order we process, product we forge, part we machine and quality test we conduct, our goal is to exceed customer expectations.

Meet the WHI Global Leadership Team

Albert Altieri

President & Chief Executive Officer

Mr. Altieri has over 35 years of management and leadership experience in the Aerospace & Defense industry. Prior to joining WHI, Mr. Altieri worked at Sikorsky Aircraft and United Technologies, beginning in 1980. He last served as Chief Operating Officer with Sikorsky Aerospace Services.

Previously, Mr. Altieri held the position of Vice President, Supply Management with Sikorsky Aircraft. Mr. Altieri holds a Bachelor of Arts in Economics from Harvard University and an MBA from the University of Connecticut. Mr. Altieri has served on the Board of Directors of Eclipse Aerospace, Stevens Manufacturing Company and M3 Technology.

Duke Peer

Executive Vice President

Sales & Marketing

Mr. Peer is an experienced sales and marketing executive with over 25 years of experience in the global aerospace, defense and industrial sectors.

Prior to joining WHI in 2015, Mr. Peer held senior sales leadership positions with Lord Corporation in the United States and Premier Farnell in the United Kingdom.

Mr. Peer holds a Bachelor of Science in Business Administration from the University of Tulsa.

Chris Hamel

Executive Vice President

Programs

Mr. Hamel has over 35 years of management and engineering experience in the aerospace and defense industry. Prior to joining WHI,

Mr. Hamel has served as Senior Vice President for Butler Aerospace & Defense, as well as Senior Vice President of the Aerostructures Group at TIGHITCO.

Mr. Hamel holds a BS in Mechanical Engineering from the University of Hartford.

Cesar Garza

Executive Vice President

Quality & Compliance

Since joining WHI in 1993, Mr. Garza has held a variety of management positions with WHI including Director of Quality,

General Manager, and President of WHI’s Fort Worth facility. Mr. Garza is currently responsible managing quality, safety and compliance at all WHI facilities.

Mr. Garza has been actively involved in a variety of industry and community organizations including serving on the board of directors of the Forging Industry Association.

Nuno Dias

Executive Vice President

Engineeringer

Mr. Dias has over 20 years of engineering experience in the aerospace and defense industry. Prior to joining WHI,

Mr. Dias served as Senior Manager at Valcor Engineering, where he was responsible for executing engineering design reviews and performing quality control inspections.

Mr. Dias began his career as CNC Programmer. Mr. Dias completed Essential Management Skills Certificate Program and Lean Six Sigma Green Belt Training at Rutgers School of Business.

Khalid Rokhami

General Manager

Crow Precision Components

Mr. Rokhami joined Crow in 1994 and has served in a wide range of functions including overseeing manufacturing processes and managing production.

Today, Mr. Rokhami works closely with the engineering and production teams at the Crow facility to develop customized forging solutions for customers..

Rocky Payton

General Manager

Tulsa Facility

Mr. Payton has over 15 years of manufacturing experience which includes working for a leading CNC machine manufacturer.

Mr. Payton has been with WHI since 2015 and his responsibilities include management and oversight of WHI’s Tulsa facility.

Mr. Payton graduated from Baker College of Muskegon.

WHI BY THE NUMBERS

72

Years in Operation

260,000

SQ. FT. Maufacturing Footprint

250

Dedicated Employees

10,000+

Tool Components & Assemblies

Schedule a Meeting with us

Let us bid on your next big project. Book a meeting and let's connect to talk about how we can help and next steps .

Follow US

WHI is a vertically integrated manufacturer of precision components and complex assemblies for diversified end markets. With industry-leading closed-die forging, composite fabrication, 3-, 4- and 5-axis CNC machining, assembly and NADCAP capabilities, WHI has served a global customer base since 1951.